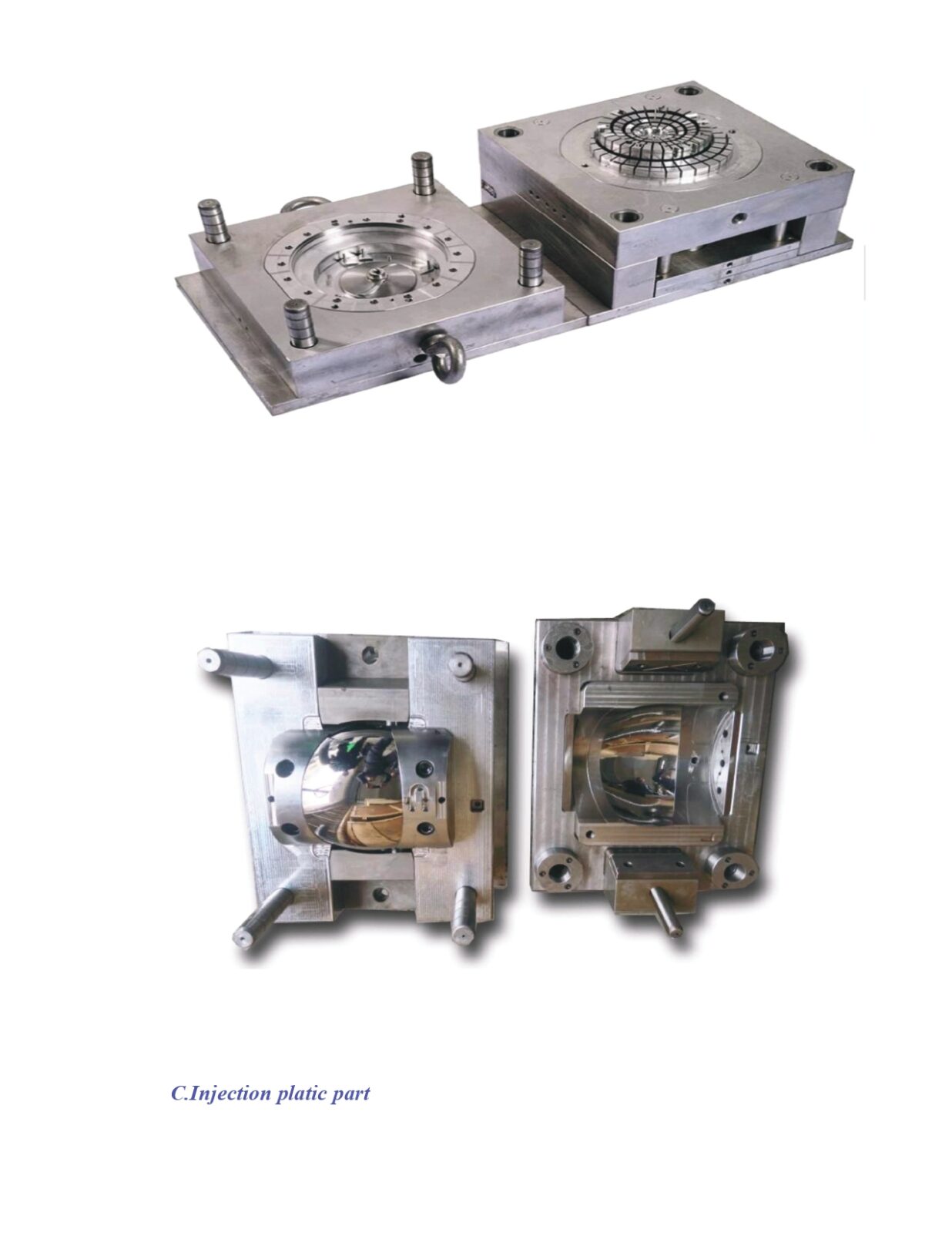

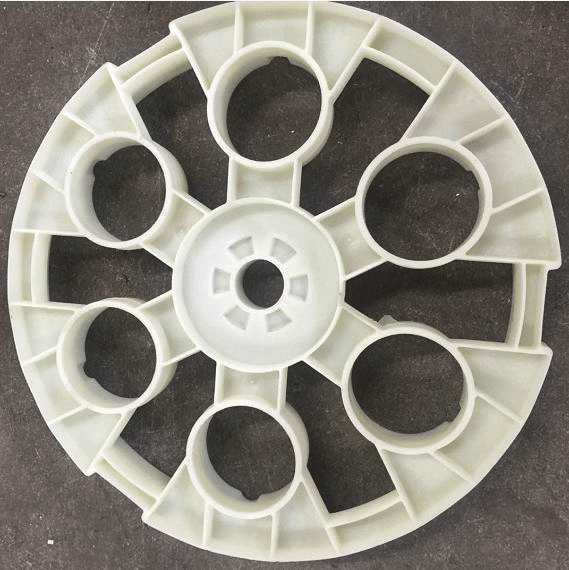

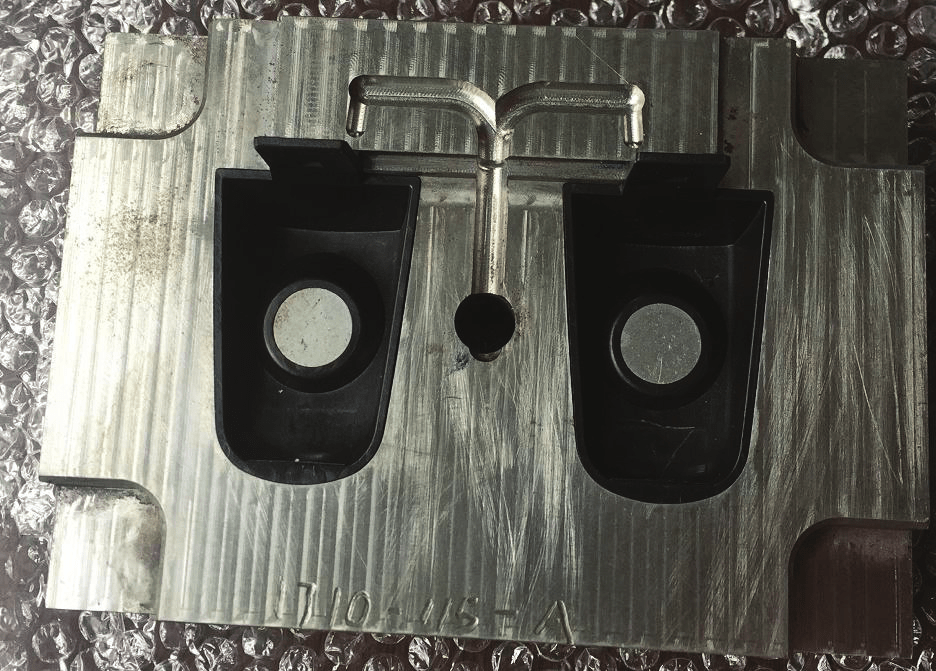

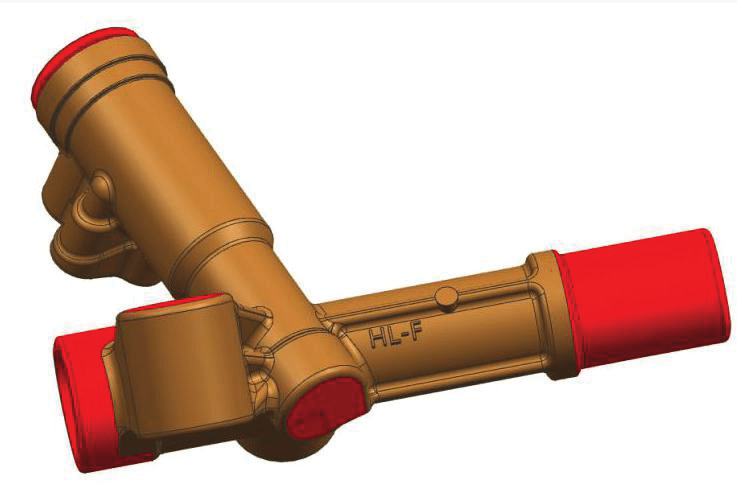

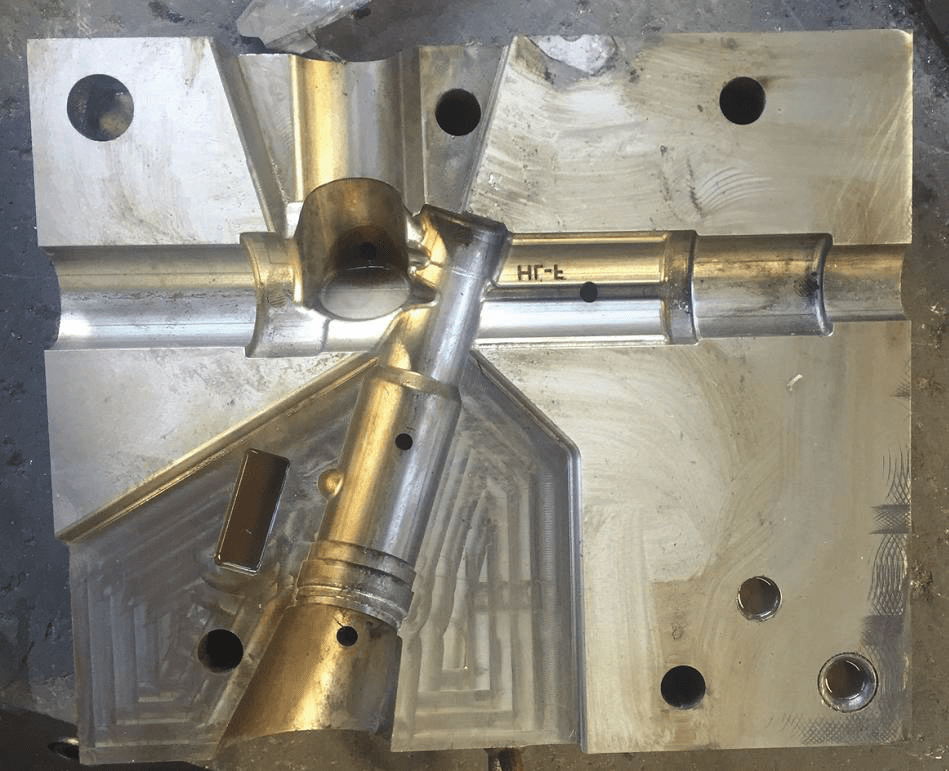

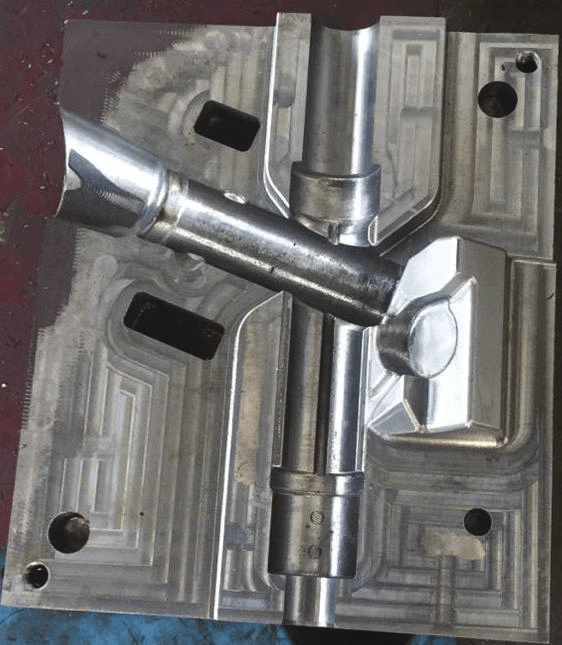

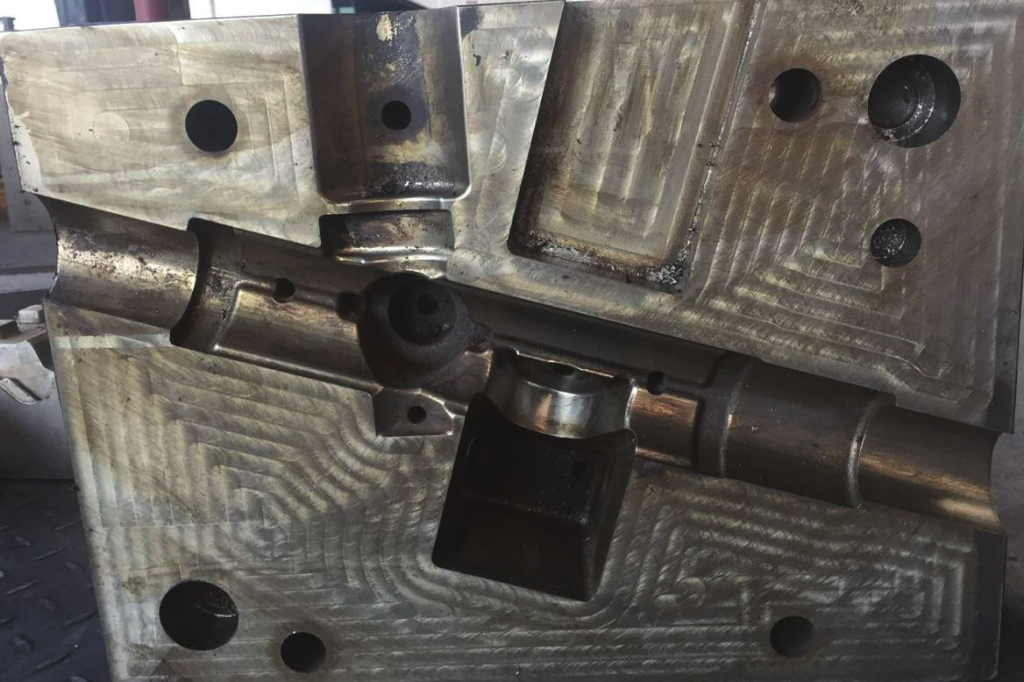

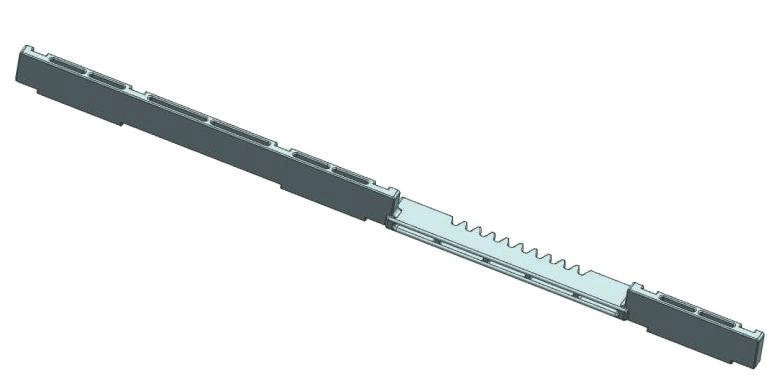

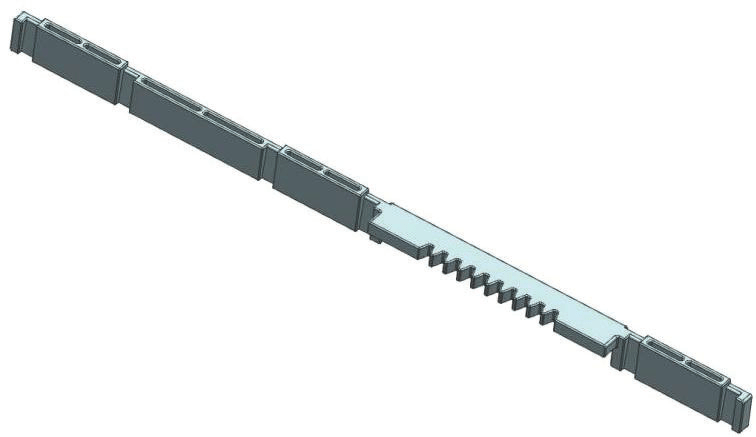

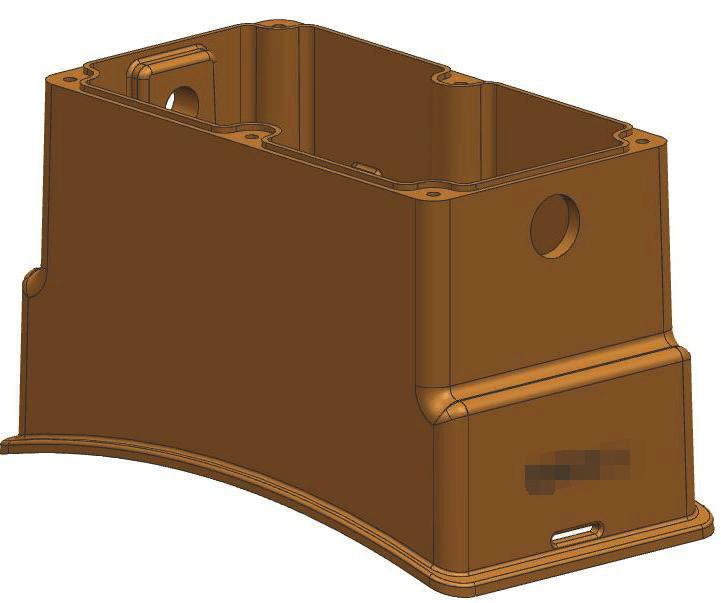

Plastic Injection tooling

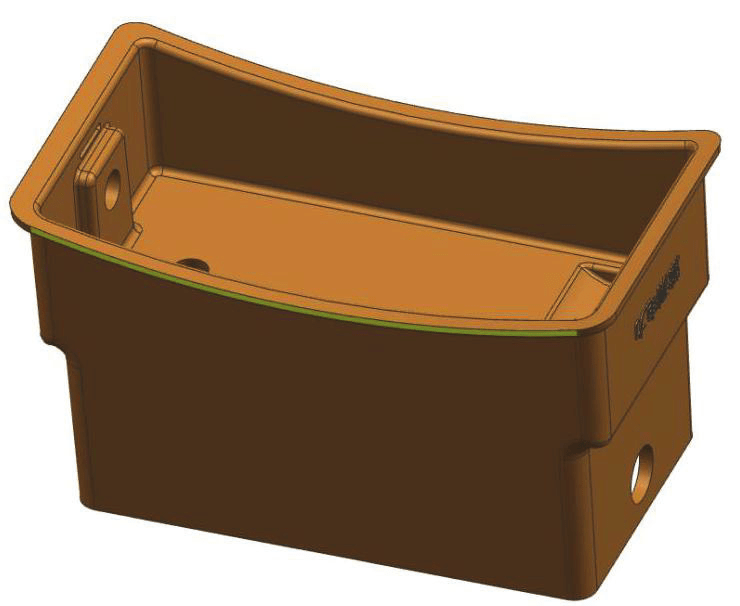

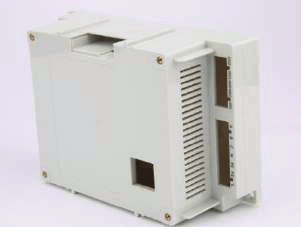

Injection molding tooling is a crucial component in the manufacturing process of plastic parts. It refers to the creation of molds or tools that are used to shape molten plastic into specific forms. These molds are typically made from steel or aluminum and are designed to withstand high temperatures and pressures. Injection molding tooling plays a vital role in achieving precise and consistent product quality, as well as enabling high production volumes. It requires expertise in design, engineering, and materials to ensure the success of the injection molding process.

Versatility and Efficiency of Plastic Injection Molding Across Industries

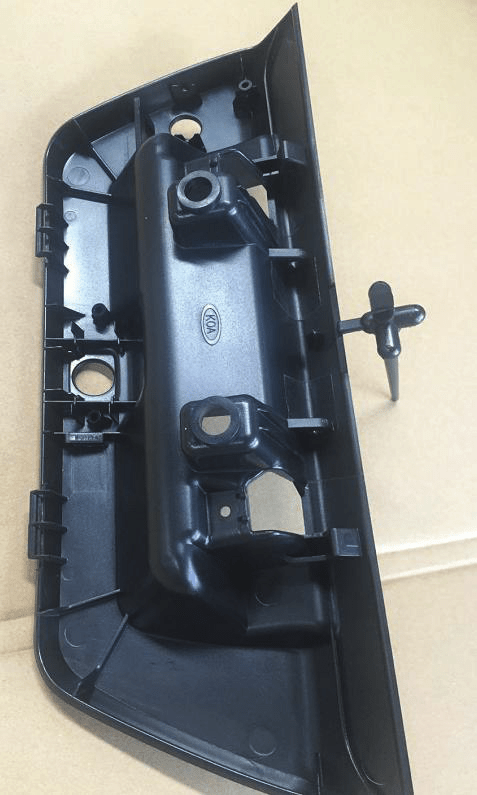

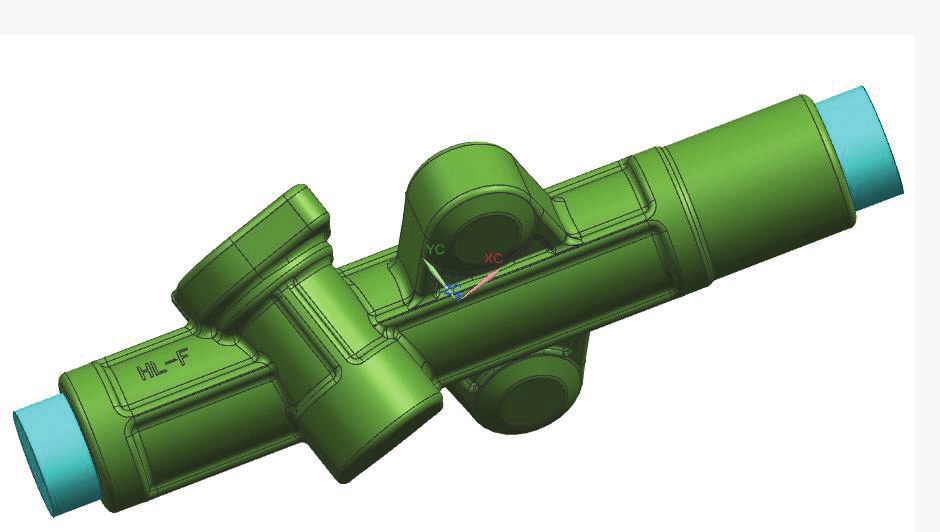

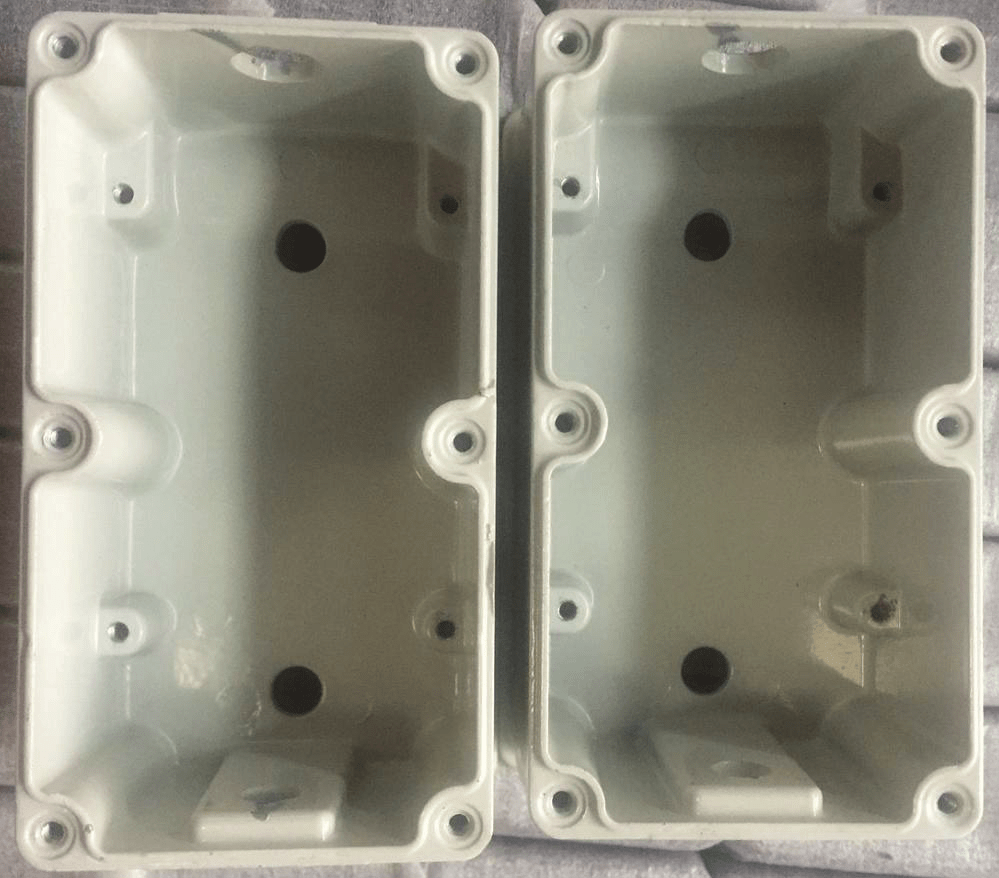

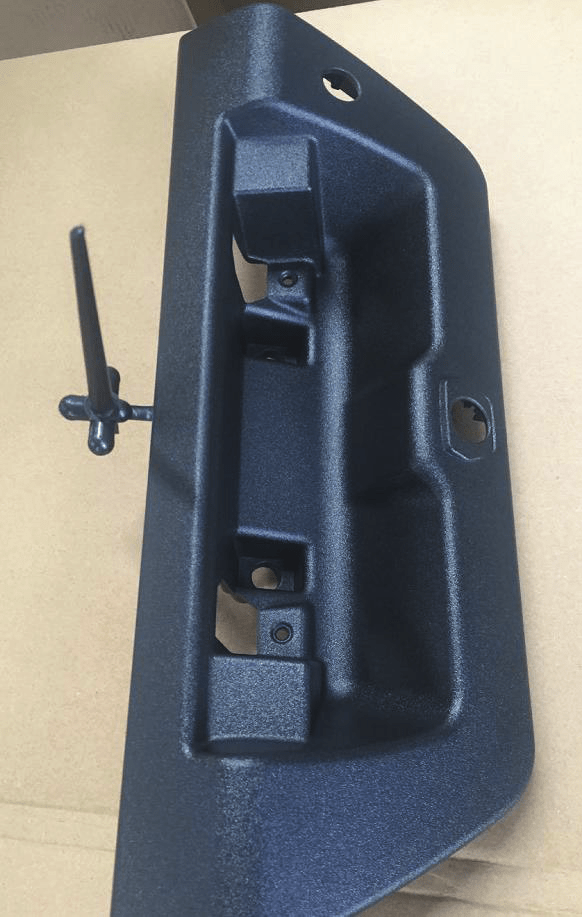

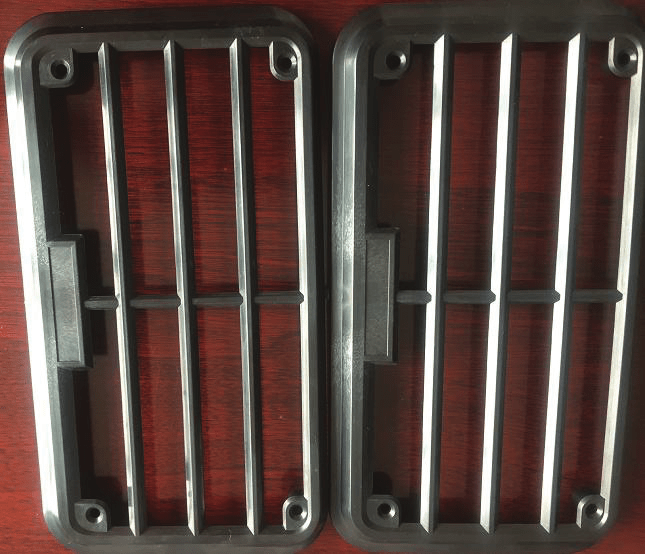

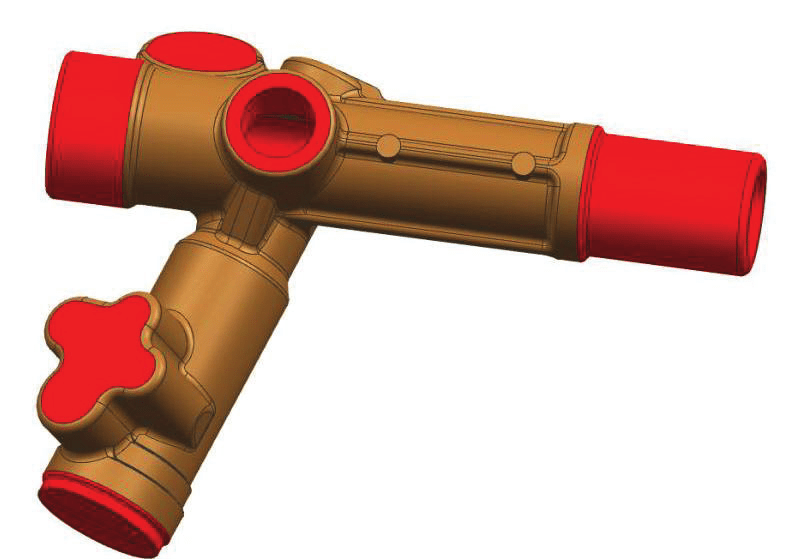

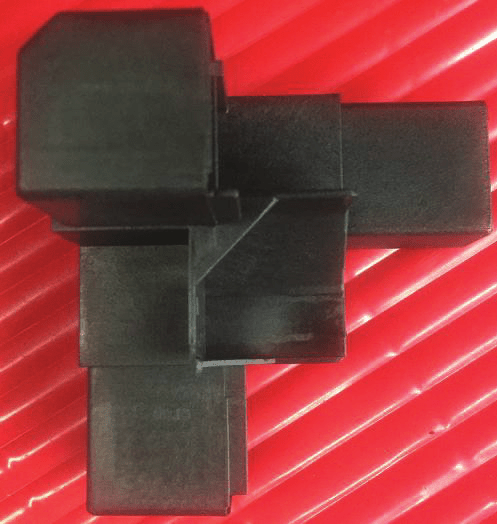

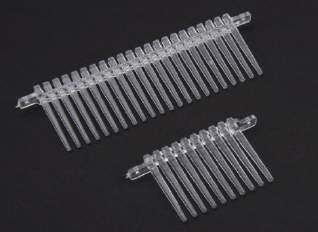

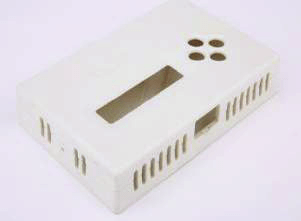

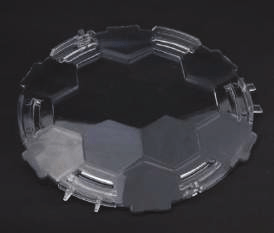

Plastic injection molding is widely used in various industries, including automotive, electronics, medical, and consumer products. It is suitable for producing a wide range of plastic parts, from small and intricate components to large and complex structures. The process allows for precise control over part dimensions, surface finish, and material properties.

Overall, plastic injection molding is a versatile and efficient manufacturing process that enables the production of high-quality plastic parts at a large scale. It is a cost-effective solution for mass production and plays a crucial role in the creation of a wide range of products that we use in our everyday lives.