Service Case

Prototyping is a crucial step in the product development process that involves creating a working model or a scaled-down version of a product idea. It serves as a tangible representation of the design concept, allowing designers and engineers to test and validate their ideas before moving forward with production. Prototyping can take various forms, from simple sketches and 3D printed models to functional prototypes that closely resemble the final product. The main goal of prototyping is to identify and address any design flaws, functionality issues, or manufacturing challenges early on, saving time and resources in the long run. Prototyping also enables stakeholders to visualize and interact with the product, providing valuable feedback and insights for further improvements. By iterating and refining the prototype, designers can fine-tune the design, optimize performance, and ensure a successful final product. Prototyping plays a vital role in reducing risks, enhancing product quality, and ultimately bringing innovative ideas to life.

Include:

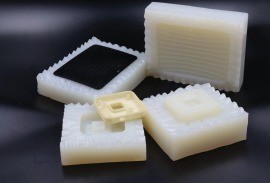

SLA :

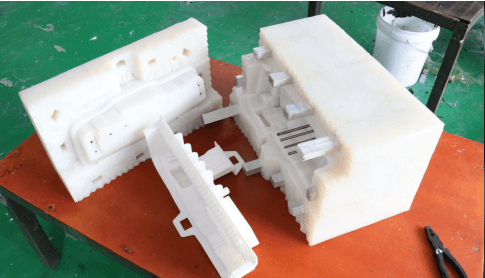

SLA (Stereolithography) and SLS (Selective Laser Sintering) are two popular additive manufacturing technologies that have revolutionized the way prototypes and functional parts are produced. SLA involves using a laser to selectively cure liquid photopolymer resin, layer by layer, to create a solid object. This process produces highly detailed and accurate parts with smooth surface finishes. On the other hand, SLS utilizes a high-powered laser to selectively fuse powdered materials, such as nylon or metal, layer by layer, to form a solid part. SLS is known for its ability to create functional and durable parts with complex geometries. Both SLA and SLS offer advantages such as the ability to produce intricate designs, rapid prototyping, and the elimination of tooling costs. These technologies are widely used in industries such as automotive, aerospace, and medical, where precision and customization are crucial. With their ability to produce high-quality parts with speed and accuracy, SLA and SLS have become invaluable tools in the world of additive manufacturing.

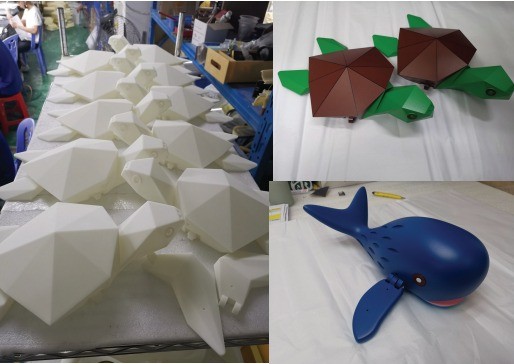

SLS:

SLS (Selective Laser Sintering) prototyping is a specific method of prototyping that utilizes the SLS additive manufacturing technology. In SLS prototyping, a high-powered laser selectively fuses powdered materials, such as nylon or metal, layer by layer, to create a solid three-dimensional object. This process allows for the production of complex geometries and functional parts with high accuracy and durability. SLS prototyping offers several advantages, including the ability to create parts with intricate details, excellent mechanical properties, and the flexibility to work with a wide range of materials. It is particularly useful in industries such as aerospace, automotive, and medical, where functional prototypes and end-use parts are required. SLS prototyping enables designers and engineers to quickly iterate and refine their designs, test for fit and function, and make necessary adjustments before moving into mass production. Overall, SLS prototyping is a powerful tool that accelerates the product development process and facilitates the creation of innovative and high-quality products.

Laser Cutting:

Laser cutting is a highly precise and versatile technology used to cut a wide range of materials with incredible accuracy. It involves using a high-powered laser beam to melt, burn, or vaporize the material, creating a clean and precise cut. The laser beam is controlled by computer software, allowing for intricate and complex designs to be cut with ease. Laser cutting offers numerous advantages, including its ability to cut various materials such as metal, wood, plastic, and fabric. It produces minimal heat-affected zones, resulting in clean edges and minimal distortion. Laser cutting is widely used in industries such as manufacturing, automotive, aerospace, and signage. It is also popular among hobbyists and artists for its ability to create intricate and detailed designs. With its precision, speed, and versatility, laser cutting has become an indispensable tool in modern manufacturing and design.