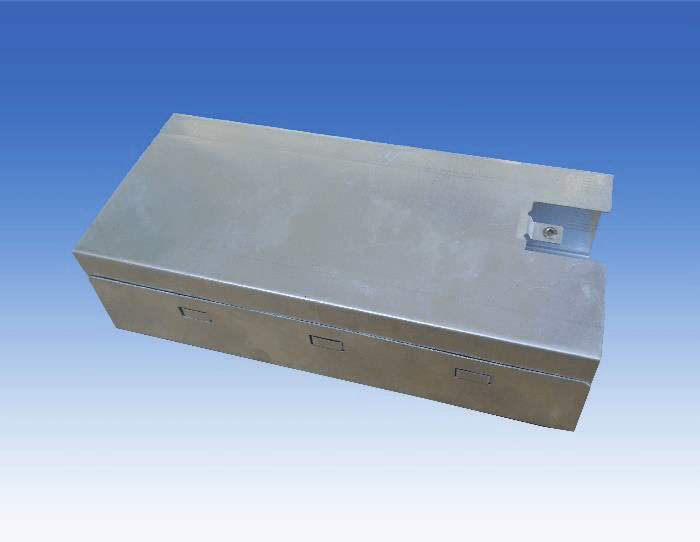

Service Case

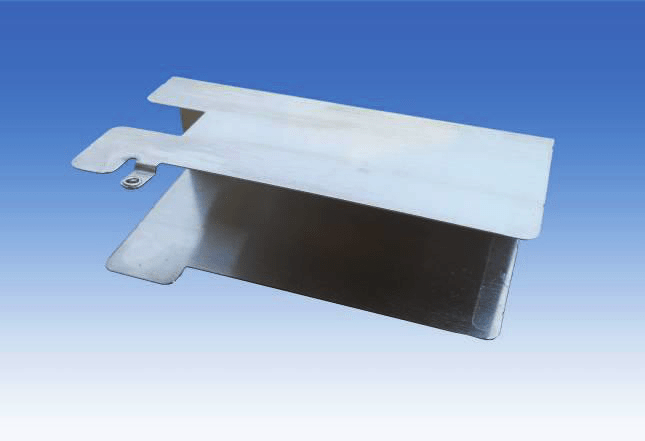

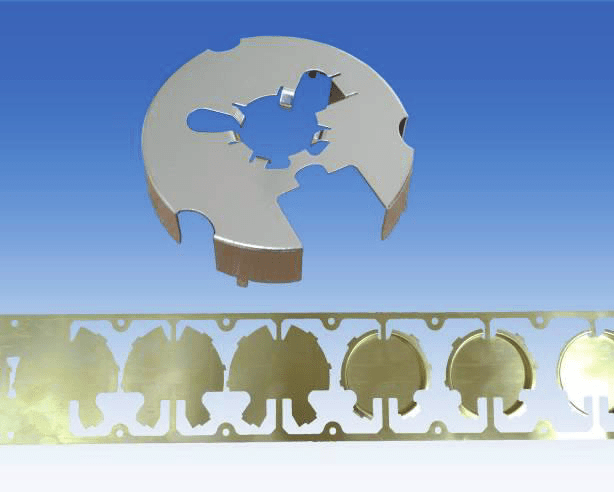

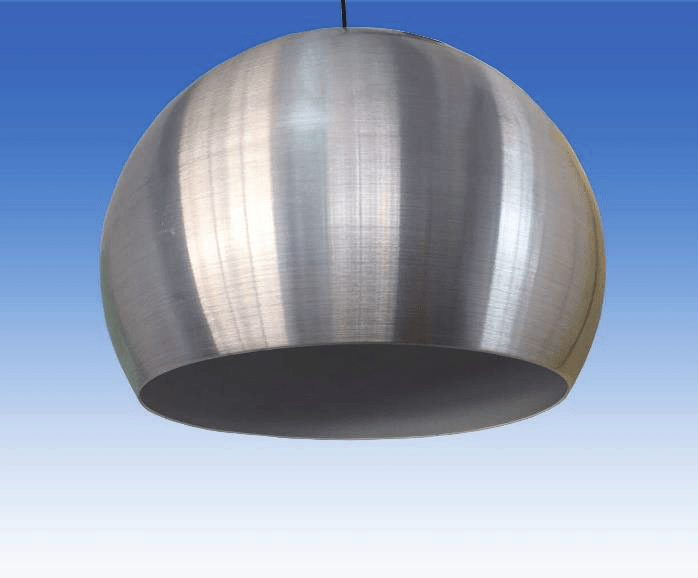

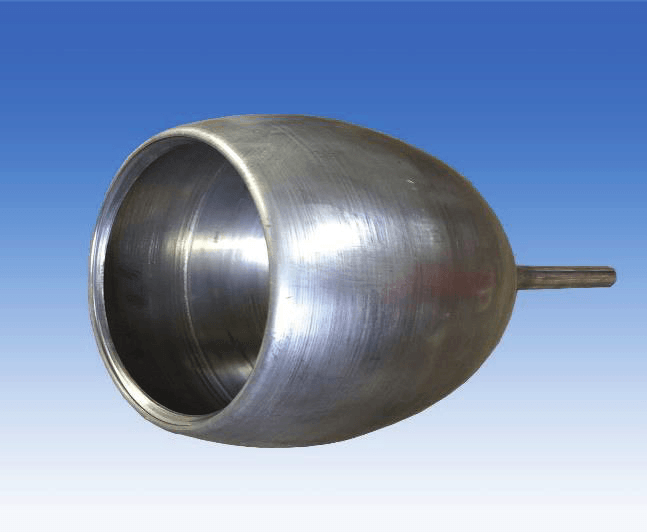

Deep drawn stamping is a cold-forming process where the depth of the final product is half as large or larger than its shorter side. This is achieved by drawing a flat metal blank into a die cavity/cavities with a punch until the metal has been shaped into the desired form. This method allows parts smaller than an inch or large enough to be used in automobiles and aerospace.

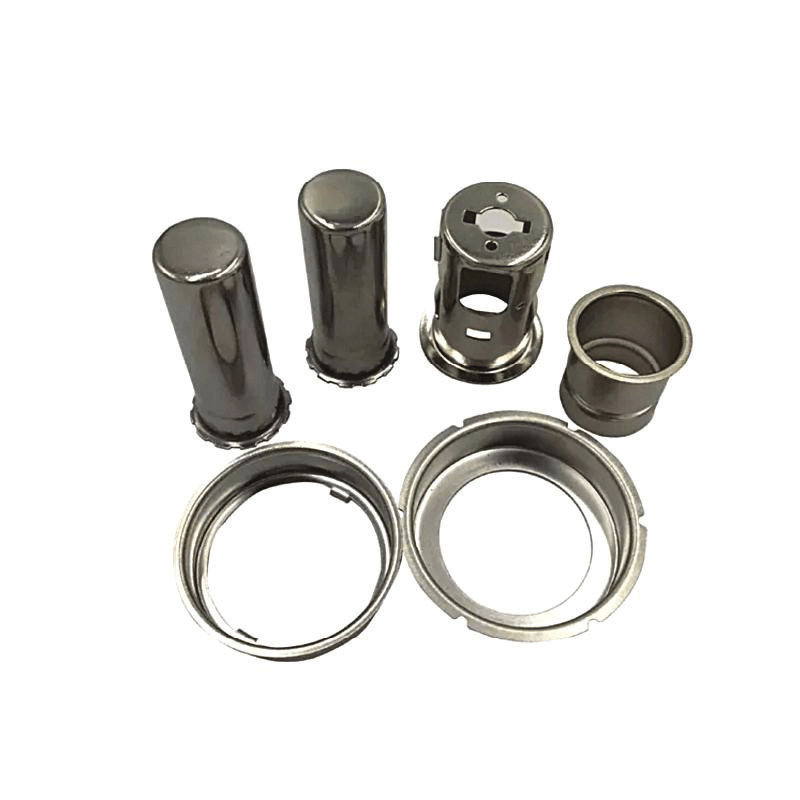

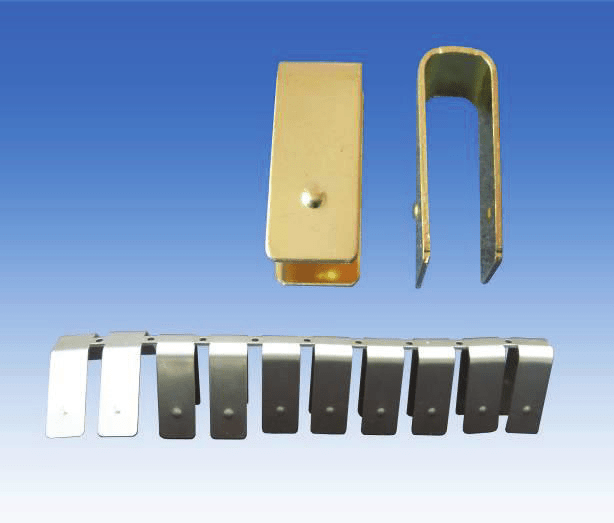

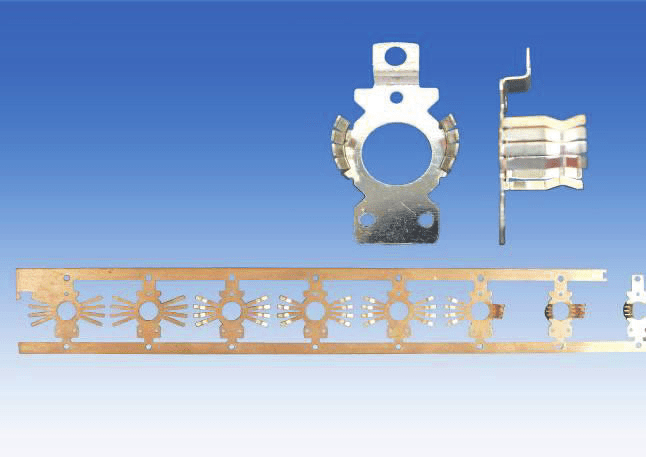

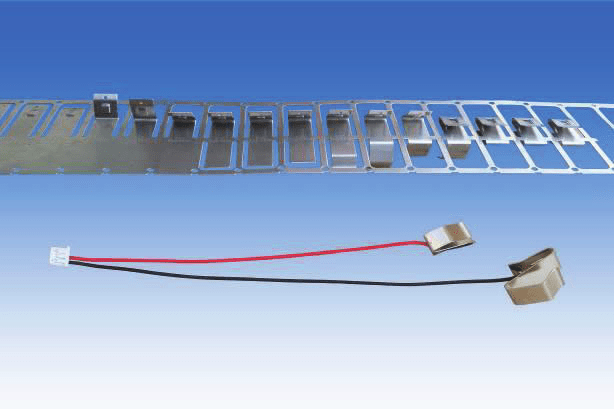

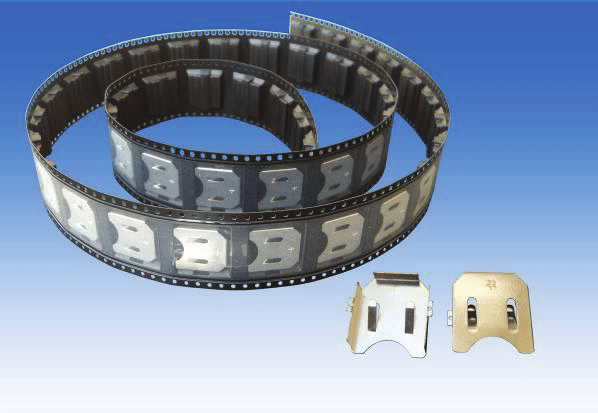

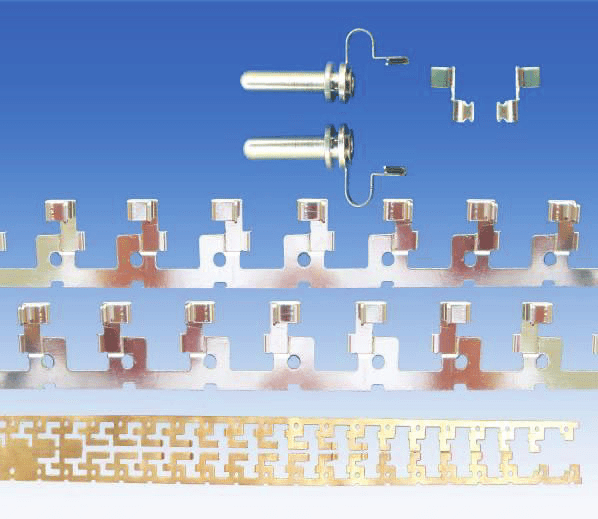

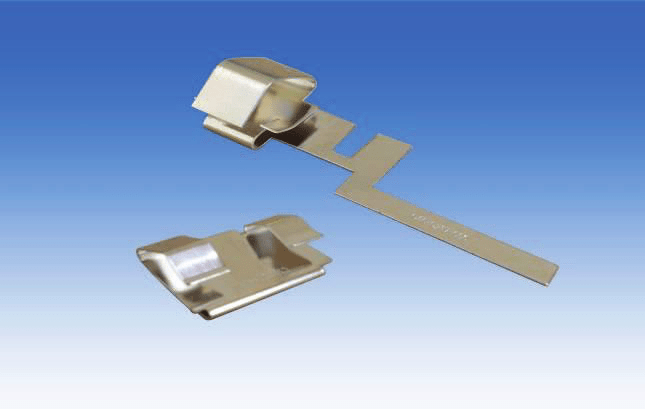

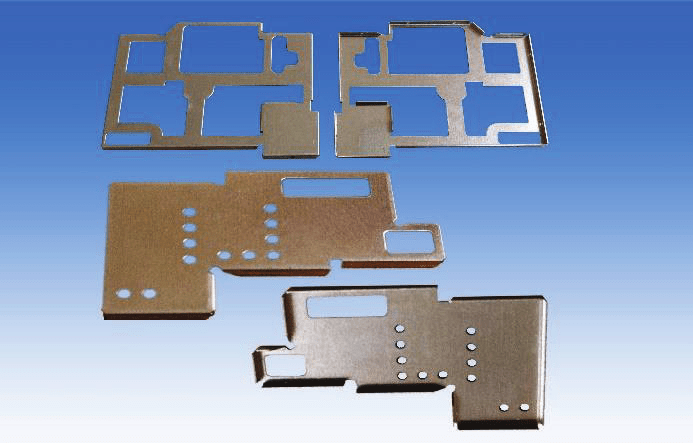

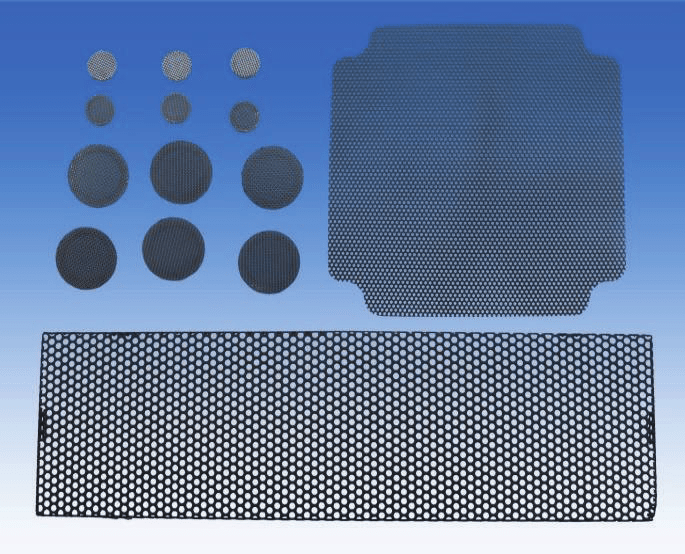

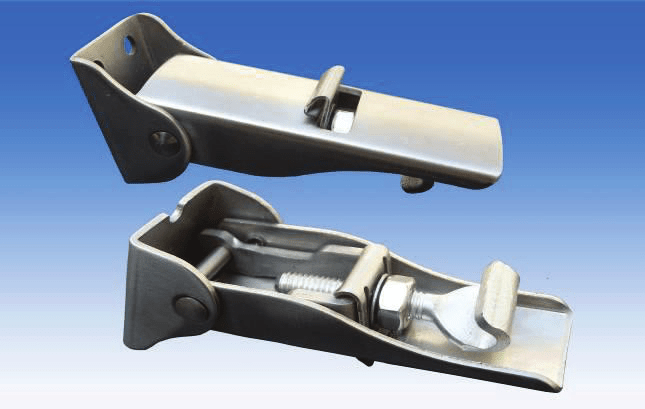

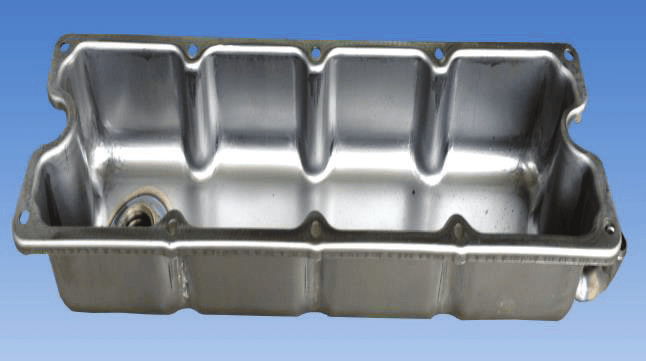

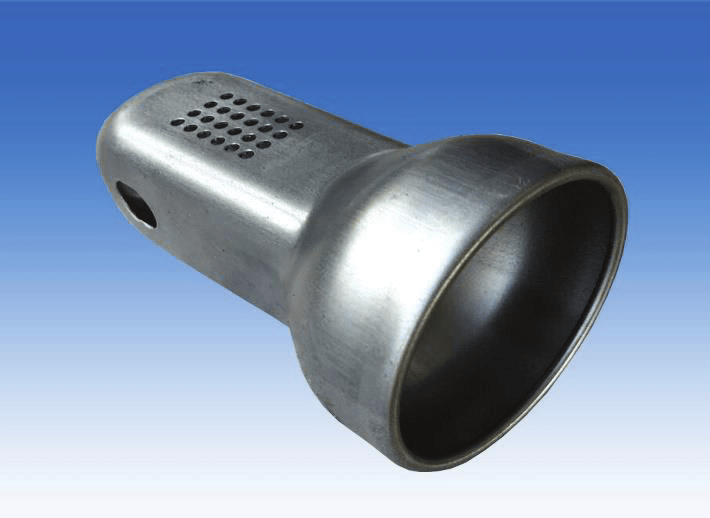

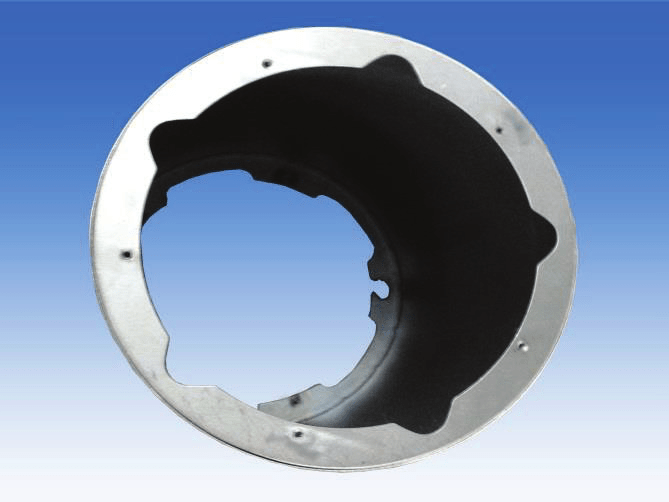

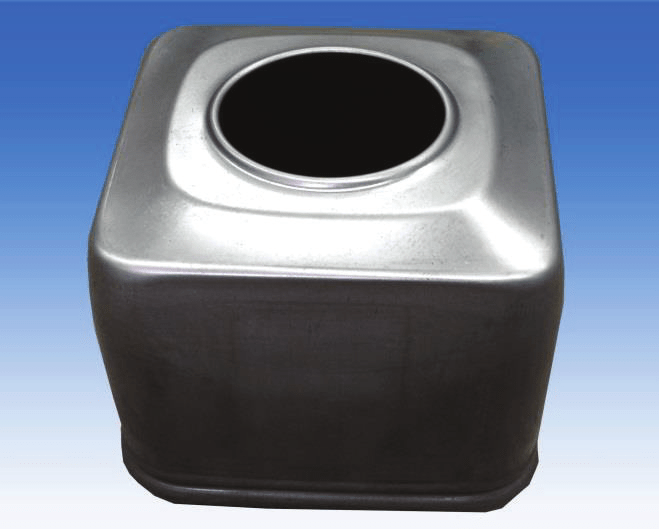

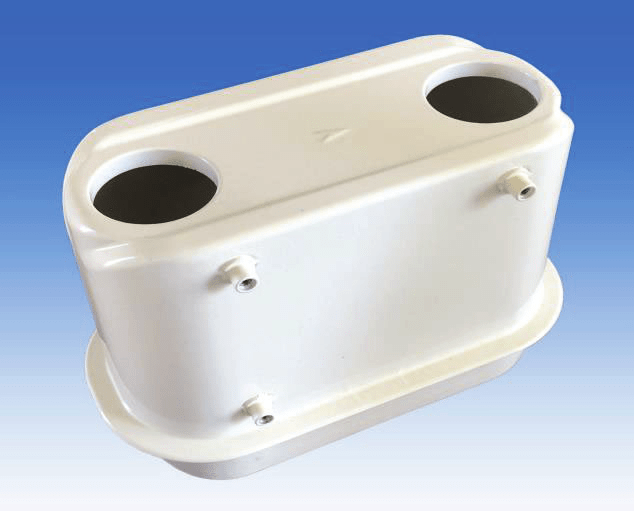

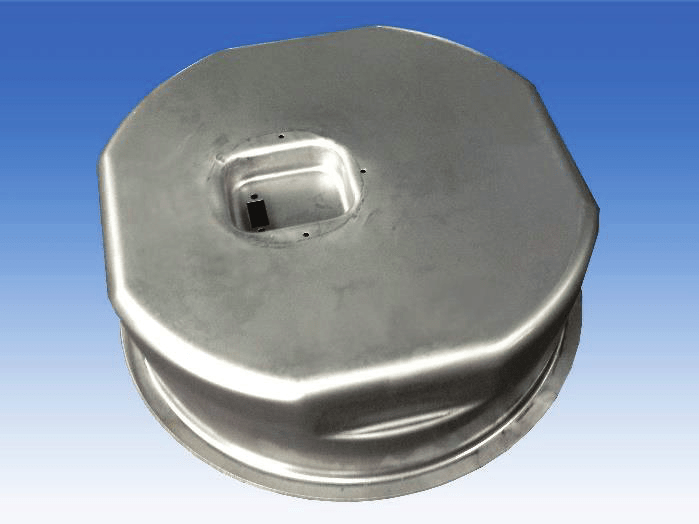

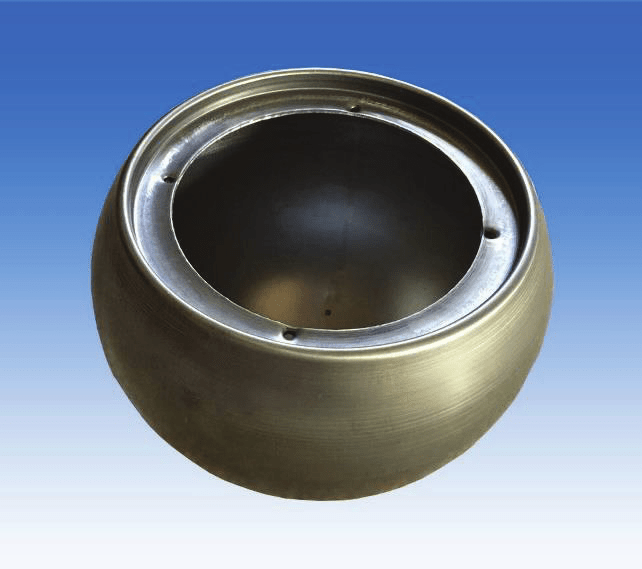

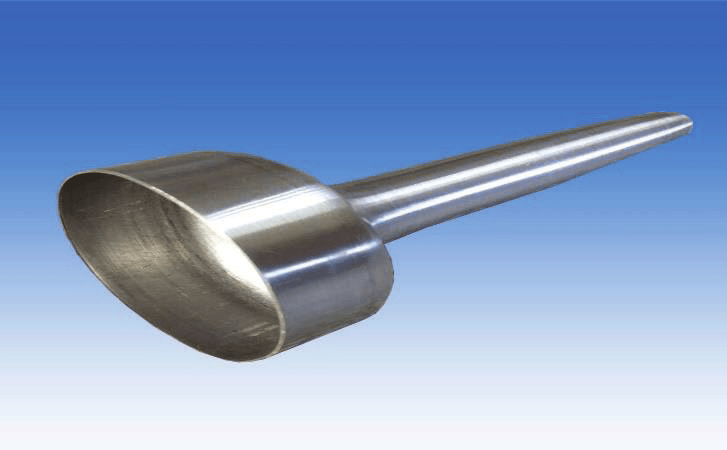

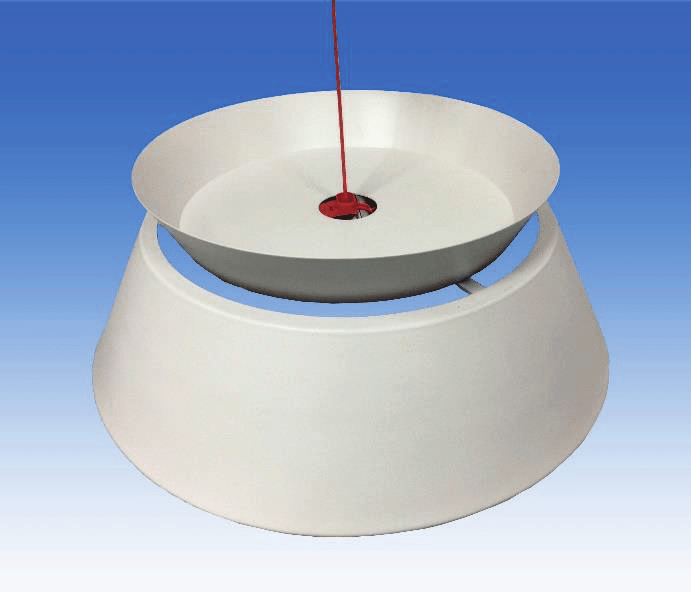

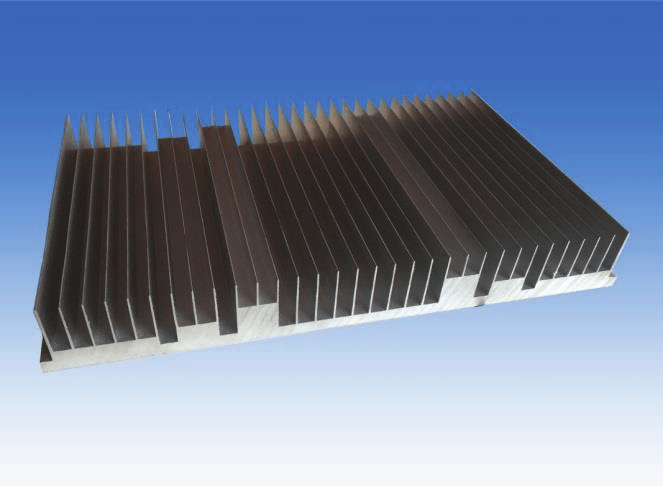

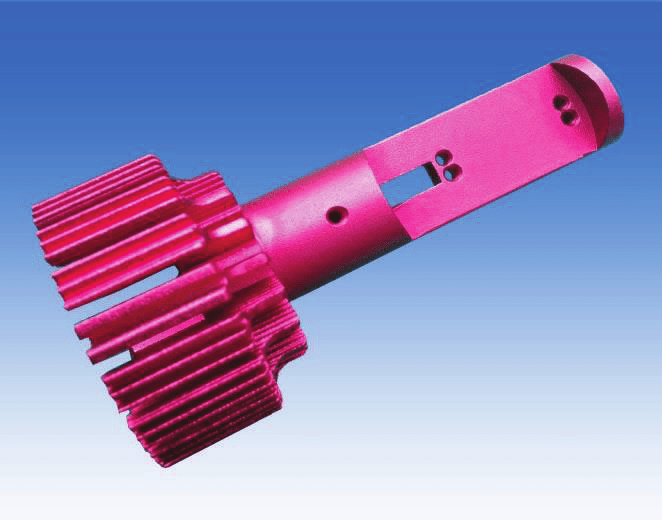

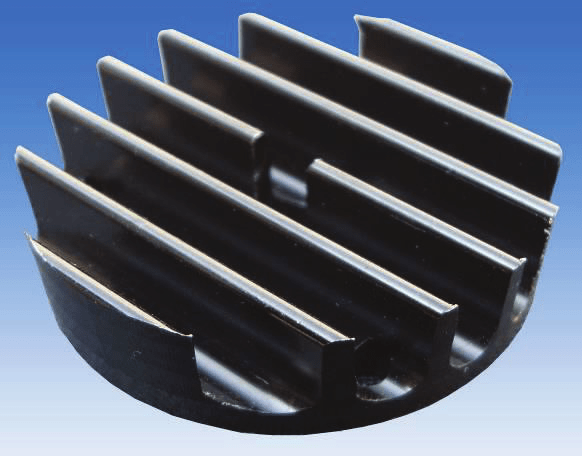

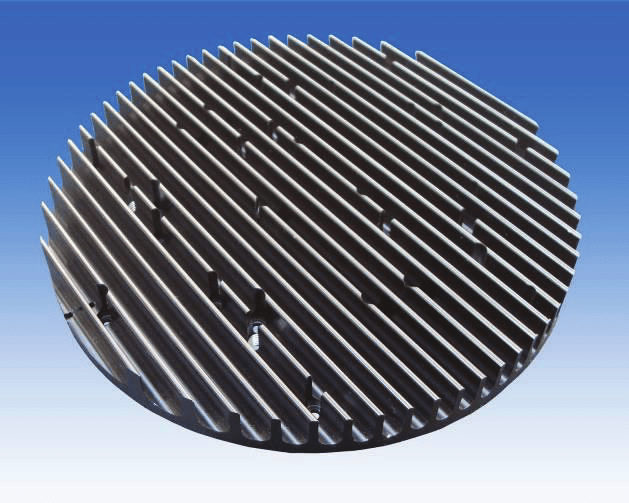

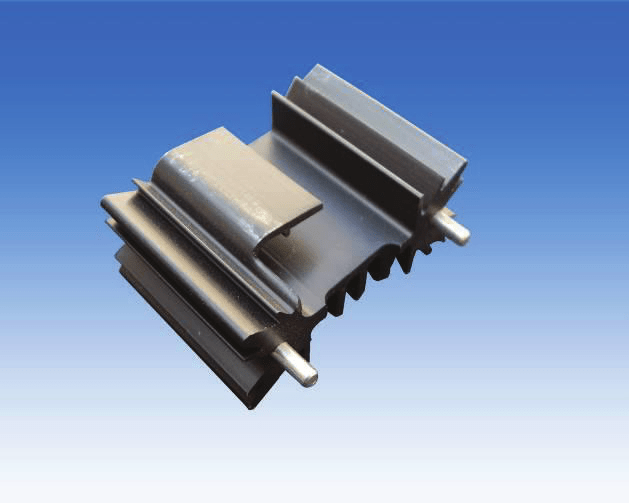

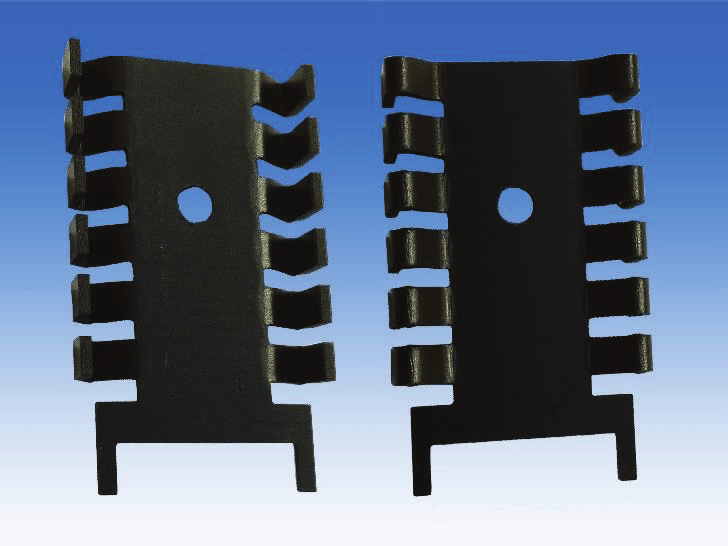

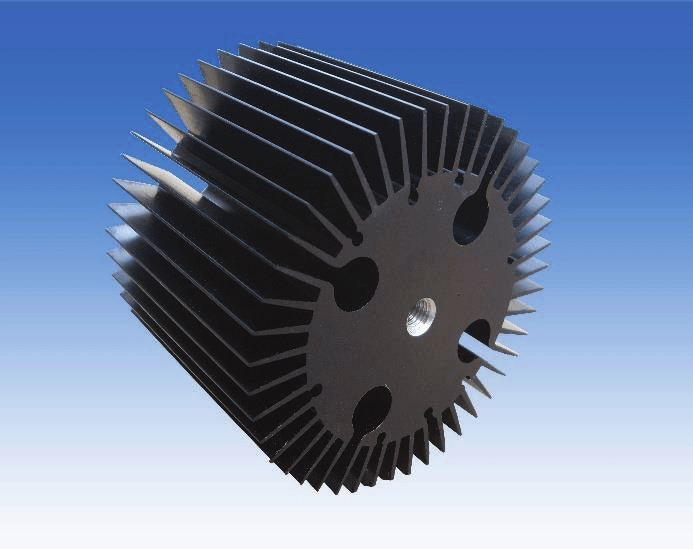

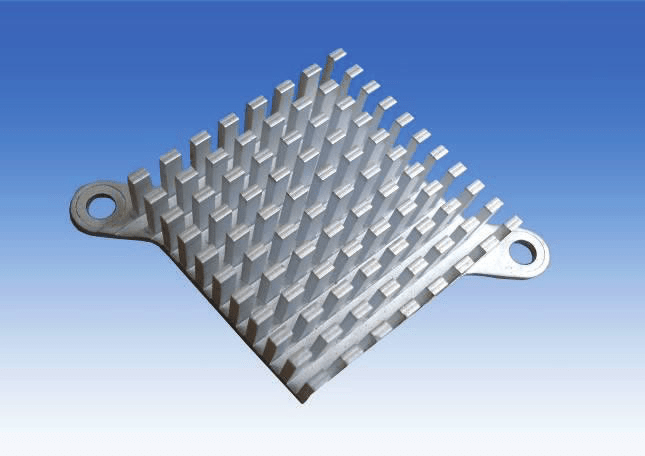

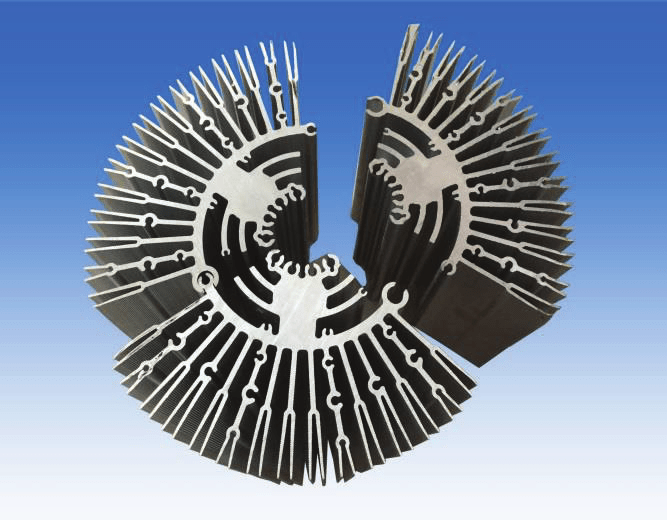

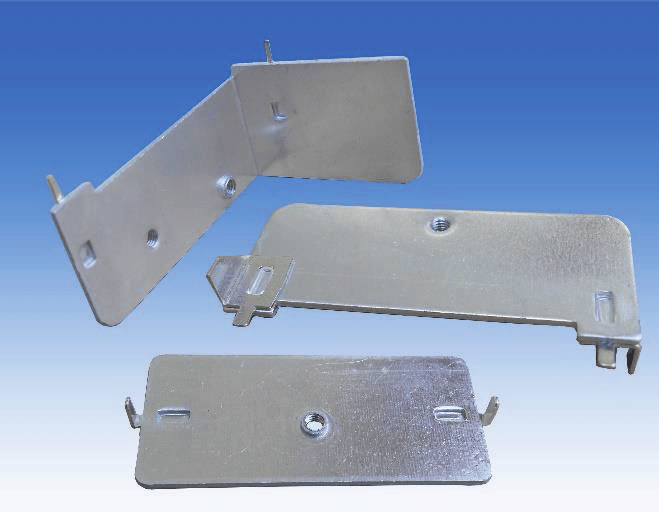

We produce e produce high-volume deep-drawn components for a variety of industries, including aerospace components, automotive components, and more. Our deep draw part capabilities include in-house tooling combined with design and engineering support for diverse applications including cans, caps, cases, connectors, cups, eyelets, ferrules, housings, shells, and more

When your project demands precision, contact us to discuss our deep draw stampings capabilities and parts.

Deep drawn parts are produced in high speed-independently cam-operated presses. Punches and dies are the tools used to draw and shape the raw material to produce the deep drawn formed part desired. The raw material used is in strip form. The first operation at the press cuts a flat blank from the strip of raw material. The blank is then carried by transfer fingers to the next operation where a cup is drawn. The cup is then transferred to the next station where the metal is drawn in a percentage allowed. It may take up to 12 of these operations to draw and shape into the final deep drawn product.

Our deep drawn stamping services can be applied to a variety of materials such as brass, copper, aluminum, stainless steel, cold rolled steel